User:James D DE/sandbox

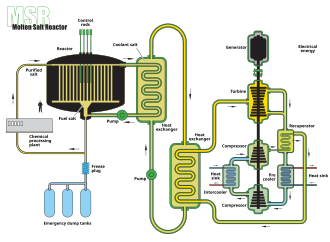

| External image | |

|---|---|

| External image | |

|---|---|

A molten salt reactor (MSR) is a class of nuclear fission reactor in which the primary nuclear reactor coolant and/or the fuel is a molten salt (mixture). MSRs' operation at or close to atmospheric pressure, rather than the 75-150 times atmospheric pressure of typical light-water reactors (LWRs), improves safety by eliminating a source of explosion risk and reduces the size and cost of the reactor's containment structures. Chemically, molten salts bind nearly all fission products, including caesium and iodine, preventing their release in an accident. MSRs' operating temperatures, higher than in a traditional LWR, offer improved electricity-generation efficiency and, in some cases, process-heat or hydrogen production opportunities. Salts' high boiling point of up to 1500°C and fuel salts' negative temperature coefficient of reactivity contribute to passive safety. The main design challenges relate to materials, which must withstand high temperatures, irradiation and the corrosivity of hot salts, and, in circulating-fuel-salt designs, managing the behaviour of the chemically-complex fuel salt as it circulates. Early estimates of MSR costs suggest they could be comparable or cheaper than LWRs.[3]

While many design variants have been proposed, there are three main categories regarding the role of molten salt. Note that the most-discussed type of MSR (thorium-fuelled breeders, e.g. LFTR) are a subtype of the "circulating fuel salt" category, but exist alongside quite different alternatives.

| Category | Examples |

|---|---|

| Molten salt fuel - circulating | ARE • MSRE • DMSR • MSFR • LFTR • IMSR • AWB, CMSR • EVOL • DFR • TMSR-500 |

| Molten salt fuel - static | SSR |

| Molten salt coolant only | TMSR • FHR |

Of these, the "original" 1950s/1960s designs (ARE/MSRE) used circulating fuel salt. A static fuel salt design has been in development since 2014. Designs using molten salt as coolant only were introduced in 2002.

In a circulating fuel salt design, the fuel salt passes through a volume where it achieves criticality, either due to the presence of a moderator (for thermal-neutron designs) or due to the dimensions of the volume (for fast-neutron designs) and then past heat exchangers which transfer the fission heat to a coolant circuit. Both pool-type and loop-type designs have been proposed. Some degree of salt purification/reprocessing is typically foreseen. In some designs, breeding can take place within the fuel salt (see for example LFTR).

In a static fuel salt design, the fuel salt is held in traditional metal fuel pins which are immersed in a pool of non-fissile coolant salt. This coolant salt circulates between the fuel pins and the heat exchangers. No circulation or purification/reprocessing of the fuel salt is foreseen, eliminating significant sources of complexity; the "price" of this simplification is having to fabricate the fuel pins/assemblies.

In a coolant salt only design, solid fuel is used (e.g. TRISO pebbles) and the (non-fissile) molten salt is the heat transfer medium to transfer fission heat to the heat exchangers.

MSRs can belong to most categories of nuclear reactors:

- They can be fast, thermal or epithermal.[4] Thermal reactors employ a moderator (usually graphite) to slow the neutrons down.

- They can be burners or breeders. A common misunderstanding is that circulating fuel salt designs are necessarily breeders, although this was a focus of much ORNL work. Some such designs include the fertile material (e.g. thorium) in the fuel salt, rather than as a separate blanket.

- They can use a variety of fuels (low-enriched uranium, thorium, depleted uranium, waste products)[5] and coolants (molten salt, liquid metal or gas). In particular the use of liquid rather than solid fuel may make it easier to use varying and impure mixes of actinides from nuclear waste without the constraints that solid fuel could impose (precise dimensions of fuel pellets, homogeneous distribution of actinides in fuel, precise tolerances on fuel behaviour under irradiation).

- They can be monolithic or modular, large or small

The lack of operating experience beyond three small R&D reactors, as well as the need for new fuel fabrication and waste disposal processes, increases the R&D/licensing effort required to bring these otherwise promising technologies to market.

History[edit]

After a major initial development push in the 1950s and 1960s at Oak Ridge National Laboratory (ORNL), including three R&D reactors which achieved criticality, a staff of 300 in the early to mid 1950s and a total expenditure on MSRs by 1973 of over $130m ($1.06bn in 2020 dollars), in the 1970s activity largely ceased. Increased research into Generation IV reactor designs in the early 2000s began to renew interest in the technology[6], and in 2011 China began a large-scale development program with 600 staff. In the 2010s a number of smaller initiatives, many of them private-sector, also began working on MSRs.

1950s[edit]

MSR research started in 1950 with the U.S. Aircraft Reactor Experiment (ARE) in support of the U.S. Aircraft Nuclear Propulsion (ANP) program. ARE was a 2.5 MWth nuclear reactor experiment designed to attain a high energy density for use as an engine in a nuclear-powered bomber.

ARE used molten fluoride salt NaF-ZrF4-UF4 (53-41-6 mol%) as fuel, moderated by beryllium oxide (BeO). The fuel salt transferred heat to a helium loop, which then transferred it to water, while liquid sodium was used to cool the moderator. The experiment had a peak temperature of 860 °C, and produced 100 MWh over nine days in 1954.[7]

In 1957 a second MSR, the Pratt and Whitney Aircraft Reactor-1 (PWAR-1), was operated at the Critical Experiments Facility of the Oak Ridge National Laboratory. It was part of the circulating-fuel reactor program of the Pratt & Whitney Aircraft Company (PWAC). The experiment was run for a few weeks and at essentially zero power, although it reached criticality. The operating temperature was held constant at approximately 675 °C (1,250 °F). The PWAR-1 used NaF-ZrF4-UF4 as the primary fuel and coolant. It was one of three critical MSRs ever built.[8]

The technical challenges of incorporating a nuclear reactor into an aircraft, together with the introduction of intercontinental ballistic missiles in 1959, led to the cancellation of the ARE's parent program, the ANP, in 1961.

1960s[edit]

ORNL began designing the Molten-Salt Reactor Experiment (MSRE) in 1960. MSRE was a 7.4 MWth test reactor using LiF-BeF2-ZrF4-UF4 (65-29-5-1) fuel moderated by pyrolytic graphite. It was designed to simulate the neutronic "kernel" of a type of epithermal thorium molten salt breeder reactor called the liquid fluoride thorium reactor (LFTR). The large (expensive) breeding blanket of thorium salt was omitted in favor of neutron measurements.

It went critical in 1965 and ran for four years. MSRE's piping, core vat and structural components were made from Hastelloy-N, and its secondary coolant was FLiBe (2LiF-BeF2). It reached temperatures as high as 650 °C and achieved the equivalent of about 1.5 years of full power operation.

Starting in the early 1960s, ORNL began work on a Molten Salt Breeder Reactor design, culminating in a single-fluid, thermal-neutron conceptual design similar to a scaled-up MSRE in 1971. Fuel was to be LiF-BeF2-ThF4-UF4 (72-16-12-0.3) with graphite moderator. The secondary coolant was to be NaF-NaBF4. Its peak operating temperature was to be 705 °C.[9] It would follow a 4-year replacement schedule.

In parallel, in 1964 the UK's Atomic Energy Research Establishment (AERE) began developing an MSR design across its National Laboratories at Harwell, Culham, Risley and Winfrith, with experimental work from 1968. AERE opted to focus on a lead-cooled 2.5 GWe Molten Salt Fast Reactor (MSFR) concept using plutonium from the UK's stockpile in chloride form.[10]. ORNL and AERE actively exchanged information during this period. AERE also researched helium gas as a coolant.[11][12]

1970s[edit]

The 1970s began at ORNL with design studies for a Molten Salt Breeder Experiment reactor (100 MWt) and a Molten Salt Demonstration Reactor (300 MWe), but the program was terminated in 1973, re-started in 1974 and then finally terminated in 1976 in favor of the liquid metal fast-breeder reactor (LMFBR),[13] after which large-scale MSR research stagnated in the United States.[14][15]. As of 2011[update], ARE, PWAR-1 and MSRE remained the only molten-salt reactors ever operated. The MSBR project received funding from 1968 to 1976 of (in 2023 dollars[16]) $77.6 million.[17]. The ORNL program was cancelled because:

- The political and technical support for the program in the United States was too thin geographically. Within the United States the technology was well understood only in Oak Ridge.[13]

- The MSR program was in competition with the fast breeder program at the time, which got an early start and had copious government development funds with contracts that benefited many parts of the country. When the MSR development program had progressed far enough to justify an expanded program leading to commercial development, the United States Atomic Energy Commission (AEC) could not justify the diversion of substantial funds from the LMFBR to a competing program.[13]

In the UK experimental work continued until 1973. In 1974 the program was cancelled in favour of the liquid sodium-cooled Prototype Fast Reactor at Dounreay.

In the USSR, a molten-salt reactor research program was started in the second half of the 1970s at the Kurchatov Institute. It included theoretical and experimental studies, particularly the investigation of mechanical, corrosion and radiation properties of the molten salt container materials. The main findings supported the conclusion that no physical nor technological obstacles prevented the practical implementation of MSRs.[18][19][20]

In 1970-71, China built a zero-power, test-scale MSR but changed course in 1972 to an LWR design.

1980s[edit]

ORNL revisited the MSR concept in 1980 in the context of proliferation resistance, examining a thermal-neutron "denatured molten salt reactor" (DMSR) fueled with low-enriched uranium (LEU) and without breeding capability, which reduced the requirement for fuel salt reprocessing.[21] In the USSR, the Kurchatov Institute continued work on MSRs, with a drop-off of activity after 1986 due to the Chernobyl accident, along with a general stagnation of nuclear power and the nuclear industry.

1990s[edit]

Some further research on MSRs was undertaken in Russia as part of an International Science and Technology Center (ISTC) project in 1994-96.

2000s[edit]

MSR interest resumed in the new millennium. In particular, the Generation IV International Forum (GIF), founded in 2000, identified MSRs in 2002 as one of 6 candidate technologies for future, "Generation IV" reactors which could improve on existing LWR technology in terms of cost, safety, waste and proliferation resistance.

Molten salt coolant only designs[edit]

Molten-salt-cooled solid-fuel reactors are variously called "molten salt reactor system" in the Generation IV proposal, Molten Salt Converter Reactors (MSCR), advanced high-temperature reactors (AHTRs), or fluoride high-temperature reactors (FHR, preferred DOE designation).[22]

FHRs cannot reprocess fuel easily and their solid fuel needs to be fabricated and validated, requiring up to ???twenty years[citation needed] from project inception. FHR retains the safety and cost advantages of a low-pressure, high-temperature coolant, also shared by liquid metal cooled reactors. Notably, steam is not created in the core (as is present in BWRs), and no large, expensive steel pressure vessel (as required for PWRs). Since it can operate at high temperatures, the conversion of the heat to electricity can use an efficient, lightweight Brayton cycle gas turbine.

(Also referred to as "fluoride salt-cooled high-temperature reactor" (FHR).[23])

This approach involves using a fluoride-salt as the coolant. Both the traditional MSR and the very-high-temperature reactor (VHTR) were selected as potential designs for study under the Generation Four Initiative (GEN-IV). One version of the VHTR under study was the Liquid-Salt Very-High-Temperature Reactor (LS-VHTR), also commonly called the Advanced High-Temperature Reactor (AHTR).[citation needed]

It uses liquid salt as a coolant in the primary loop, rather than a single helium loop. It relies on "TRISO" fuel dispersed in graphite. Early AHTR research focused on graphite in the form of graphite rods that would be inserted in hexagonal moderating graphite blocks, but current studies focus primarily on pebble-type fuel.[citation needed] The LS-VHTR can work at very high temperatures (the boiling point of most molten salt candidates is >1400 °C); low-pressure cooling that can be used to match hydrogen production facility conditions (most thermochemical cycles require temperatures in excess of 750 °C); better electric conversion efficiency than a helium-cooled VHTR operating in similar conditions; passive safety systems and better retention of fission products in the event of an accident.[citation needed]

2010s[edit]

China[edit]

In 2011 China began the largest MSR program since the ARE, with 600 full-time staff working on the Thorium Molten Salt Reactor (TMSR). This is led by the Chinese Academy of Sciences (CAS) via the Shanghai Institute of Applied Physics (SINAP). It aims to develop both liquid fuel and solid fuel versions (TMSR-LF and TMSR-SF respectively) with the long-term goal of a closed, thorium-based fuel cycle to give China independence from uranium imports.

China initiated a thorium molten-salt reactor research project in January 2011.[24] A 100 MW demonstrator of the solid fuel version (TMSR-SF), based on pebble bed technology, planned to be ready by 2024. Initially, a 10 MW pilot and a larger demonstrator of the liquid fuel (TMSR-LF) variant were targeted for 2024 and 2035, respectively.[25][26] China then accelerated its program to build two 12 MW reactors underground at Wuwei research facilities in Gansu Province by 2020,[27] beginning with the TMSR-LF1 prototype.[28] Heat from the thorium molten-salt reaction would be used to produce electricity, hydrogen, industrial chemicals, desalination and minerals.[27] The project also seeks to test new corrosion-resistant materials.[27]

Non-China: Commercial[edit]

An increased interest in low-carbon energy sources and dissatisfaction with large-scale LWRs (safety but at high cost, unresolved waste issues) also led to a wave of nuclear energy startups (fission and fusion), including several working on MSRs:

Circulating fuel salt designs (non-thorium)[edit]

Terrestrial Energy, based in Canada, is developing a DMSR design called the Integral Molten Salt Reactor (IMSR). The IMSR is designed to be deployable as a small modular reactor (SMR). Their design currently undergoing licensing is 400MW thermal (190MW electrical). With high operating temperatures, the IMSR has applications in industrial heat markets as well as traditional power markets. The main design features include neutron moderation from graphite, fueling with low-enriched uranium and a compact and replaceable core unit. Decay heat is removed passively using nitrogen (with air as an emergency alternative). The latter feature permits the operational simplicity necessary for industrial deployment.[29] Terrestrial completed the first phase of a prelicensing review by the Canadian Nuclear Safety Commission in 2017, which provided a regulatory opinion that the design features are generally safe enough to eventually obtain a license to construct the reactor.[30]

Seaborg Technologies is developing the core for a Compact Molten Salt Reactor (CMSR). The CMSR is a high temperature, single salt, thermal MSR designed to go critical on commercially available low enriched uranium. The CMSR design is modular, and uses proprietary NaOH moderator.[31] The reactor core is estimated to be replaced every 12 years. During operation, the fuel will not be replaced and will burn for the entire 12-year reactor lifetime. The first version of the Seaborg core is planned to produce 250 MWth/100 MWe. As a power plant, the CMSR will be able to deliver electricity, clean water and heating/cooling to around 200,000 households.[32]

Transatomic Power pursued what it termed a Waste-Annihilating Molten Salt Reactor (acronym WAMSR), intended to consume existing spent nuclear fuel,[33] from 2011 until ceasing operation in 2018.[34]

Terrapower and Southern Company are collaborating to develop a Molten Chloride Fast Reactor

Circulating fuel salt designs (thorium)[edit]

Kirk Sorensen, former NASA scientist and chief nuclear technologist at Teledyne Brown Engineering, is a long-time promoter of the thorium fuel cycle, coining the term liquid fluoride thorium reactor. In 2011, Sorensen founded Flibe Energy, a company aimed at developing 20–50 MW LFTR reactor designs to power military bases. (It is easier to approve novel military designs than civilian power station designs in the US nuclear regulatory environment).[35][36][37][38]

Reactors containing molten thorium salt, called liquid fluoride thorium reactors (LFTR), would tap the thorium fuel cycle. Private companies from Japan, Russia, Australia and the United States, and the Chinese government, have expressed interest in developing this technology.[24][39][35]

Advocates estimate that five hundred metric tons of thorium could supply U.S. energy needs for one year.[40] The U.S. Geological Survey estimates that the largest-known U.S. thorium deposit, the Lemhi Pass district on the Montana-Idaho border, contains thorium reserves of 64,000 metric tons.[41]

Traditionally, these reactors were known as Molten Salt Breeder Reactors (MSBRs) or Thorium Molten Salt Reactors (TMSRs), but the name LFTR was promoted as a rebrand in the early 2000s by Kirk Sorensen.

Thorcon is developing the TMSR-500 molten salt reactor for the Indonesian market.

The Fuji Molten Salt Reactor is a 100 to 200 MWe LFTR, using technology similar to the Oak Ridge project. A consortium including members from Japan, the U.S. and Russia are developing the project. The project would likely take 20 years to develop a full size reactor,[42] but the project seems to lack funding.[39]

Copenhagen Atomics is a Danish molten salt technology company developing mass manufacturable molten salt reactors. The Copenhagen Atomics Waste Burner is a single-fluid, heavy water moderated, fluoride-based, thermal spectrum and autonomously controlled molten salt reactor. This is designed to fit inside of a leak-tight, 40-foot, stainless steel shipping container. The heavy water moderator is thermally insulated from the salt and continuously drained and cooled to below 50 °C. A molten lithium-7 deuteroxide (7LiOD) moderator version is also being researched. The reactor utilizes the thorium fuel cycle using separated plutonium from spent nuclear fuel as the initial fissile load for the first generation of reactors, eventually transitioning to a thorium breeder.[43] Copenhagen Atomics is actively developing and testing valves, pumps, heat exchangers, measurement systems, salt chemistry and purification systems, and control systems and software for molten salt applications.[44]

The German Institute for Solid State Nuclear Physics in Berlin has proposed the Dual fluid reactor as a concept for a fast breeder lead-cooled MSR. The original MSR concept used the fluid salt to provide the fission materials and also to remove the heat. Thus it had problems with the needed flowspeed. Using 2 different fluids in separate circles solves the problem.[citation needed]

Static fuel salt designs[edit]

The Stable Salt Reactor, designed by Moltex Energy, was selected as the most suitable of six MSR designs for UK implementation in a 2015 study commissioned by the UK's innovation agency, Innovate UK.[45] UK government support has been weak,[46] but Moltex has obtained support from New Brunswick Power for the development of a pilot plant in Point Lepreau, Canada,[47] and financial backing from IDOM (an international engineering firm)[48] and is currently engaged in the Canadian Vendor Design Review process.[49]

The Stable Salt Reactor is a relatively recent concept which holds the molten salt fuel statically in traditional LWR fuel pins. Pumping of the fuel salt, and all the corrosion/deposition/maintenance/containment issues arising from circulating a highly radioactive, hot and chemically complex fluid, are no longer required. The fuel pins are immersed in a separate, non-fissionable fluoride salt which acts as primary coolant.

Non-China: Government-led research[edit]

France/Europe: The CNRS project EVOL (Evaluation and viability of liquid fuel fast reactor system) project, with the objective of proposing a design of the MSFR (Molten Salt Fast Reactor),[50] released its final report in 2014.[51] R& Various MSR projects like FHR, MOSART, MSFR, and TMSR have common R&D themes.[52]

- SAMOFAR final report; SAMOSAFER ***

The EVOL project has been continued by the EU-funded Safety Assessment of the Molten Salt Fast Reactor (SAMOFAR) project, in which several European research institutes and universities collaborate.[53]

In 2015, Indian researchers published a MSR design,[54] as an alternative path to thorium-based reactors, according to India's three-stage nuclear power programme.[55]

In January 2016, the United States Department of Energy announced a $80m award fund to develop Generation IV reactor designs.[56] One of the two beneficiaries, Southern Company will use the funding to develop a Molten Chloride Fast Reactor (MCFR), a type of MSR developed earlier by British scientists.[10]

Design[edit]

Main design choices:

- salt (fuel and/or secondary/coolant)

- reactor components

- reactor layout

- salt purification

- salt reprocessing (incl. proliferation aspects)

- molten salt-specific passive safety features

Salt[edit]

The choice of salt, typically a mixture of metal halides, must consider aspects of:

- Temperature stability: this determines the operating temperature window of the reactor, with appropriate margins to salt freezing and boiling temperatures. Often a eutectic mixture of salts is chosen, thus a lower melting point, a largely unchanged boiling point and hence a wider operating temperature range.

- Corrosivity: both chlorides and fluorides are highly corrosive of metals unless kept in a strongly reducing state

- Neutron scattering/absorption behaviour: to what extent do salt components scatter and hence slow neutrons? How readily do salt components absorb neutrons, and into which elements/isotopes are they then transmuted? For example, 6Li in lithium-containing salts such as FLiBe produces radioactive and highly mobile tritium under neutron irradiation. For thermal-neutron reactors, this can be reduced by isotopically purifying the lithium to eliminate 6Li. Equally, chlorine-35 can absorb a neutron and decay to sulfur-36. If this is to be avoided, the chlorine must be isotopically purified to eliminate the 35Cl.

- Fission product binding - both chlorides and fluorides form stable compounds with fission products (FPs), excepting noble gases and noble metals.

- Thermal transport - heat capacity

- Viscosity - both to determine pumping effort (or sufficiency of natural convection) and to evaluate the risk of erosion of structural materials

Typical metals considered are Na, K, Zr, Li, Be Typical halides considered are F, Cl

What constitutes an "optimal" salt will depend on other aspects of the design (circulating/static fuel salt / solid fuel; neutron spectrum; ...)

Reactor components[edit]

Structural materials, pumps, heat exchangers and instrumentation in an MSR must be able to withstand high temperatures, high neutron fluxes (depending on location in the reactor, and on reactor neutron spectrum) and must be resistant to corrosion by the salts used as well as to more subtle effects (in the MSRE intragrain infiltration of tellurium was noted). These effects can interact with each other.

Empirically validating the suitability of specific materials requires thousands of hours of testing in specialised test facilities, of which there are only a limited number. The original ORNL development programme, starting with the ARE, generated considerable experimental data, focusing in particular on a nickel-based alloy, Hastelloy-N, as well as a proposed optimisation. Other materials which have been proposed include 316 SS, ...

In view of the complex demands on materials, some MSR designs foresee regular replacement/retirement of materials: for example, Terrestrial Energy's IMSR foresees swapping out the entire core module every 7 years, Thorcon replaces the primary loop every 4 years, while Moltex' SSR restricts the most challenging materials requirements to the fuel pins/assemblies, which are replaced every 2-4 years.

In 2017, ANSTO/Shanghai Institute Of Applied Physics announced the creation of a NiMo-SiC alloy for use in MSRs.[57][58]

Reactor layout[edit]

Principal choices include:

- fuel containment: Loop-type and pool-type circulating fuel salt designs, or static fuel salt confined to pins. Loop-type and pool-type designs must consider the different temperatures (hotter/cooler) and pressures (higher/lower) experienced by the circulating fuel salt and the resulting risk that salt components will deposit out onto reactor surfaces, heat exchangers and pumps when lower temperatures or pressures reduce their solubility. Circulating fuel salt designs must also consider how the neutron economy is affected by "delayed neutrons" emitted by reactions subsequent to fission after the radionuclides have left the reaction chamber.

- subsequent coolant loops including coolants used (typically salt or molten metal)

- breeding blankets, if the reactor is a breeder and the thorium is not dissolved in the fuel salt (LINK LFTR 1-salt type)

Salt purification[edit]

impurities with corrosion risk; (thermal) neutron poisons / fission products.

Circulating fuel salt designs typically foresee some degree of salt purification, to manage/remove unwanted elements such as fission products (in particular neutron poisons in thermal-neutron reactors) as well as oxides, sulfur and metal impurities. The chemical complexity of fuel salts (ca. 25 fission product elements plus multiple actinides/lanthanides), their high temperatures and intense radioactivity make this a non-trivial task and add a source of accident risk[59]: 15 which can trigger release of radio isotopes. Techniques for preparing and handling molten salt were first developed at ORNL.[60] Oxides could result in the deposition of solid particles in reactor operation. Sulfur must be removed because of its corrosive attack on nickel-based alloys at operational temperature. Structural metal such as chromium, nickel, and iron must be removed for corrosion control. A water content reduction purification stage using HF and helium sweep gas was specified to run at 400 °C. Oxide and sulfur contamination in the salt mixtures were removed using gas sparging of HF – H2 mixture, with the salt heated to 600 °C.[60]: 8 Structural metal contamination in the salt mixtures were removed using hydrogen gas sparging, at 700 °C.[60]: 26 Solid ammonium hydrofluoride was proposed as a safer alternative for oxide removal.[61]

The fuel purification/processing can be online (interventions in the fuel salt as it circulates) or offline (removing fuel salt in batches for purification/processing).

Designs without circulating fuel salt (static fuel salt, or solid fuel) must also practise a lesser degree of purification on the coolant salt, to remove transmutation products and water. Wire sponges.

Salt reprocessing (incl. proliferation aspects)[edit]

The possibility of online processing can be an MSR advantage. Continuous processing would reduce the inventory of fission products, control corrosion and improve neutron economy by removing fission products with high neutron absorption cross-section, especially xenon. This makes the MSR particularly suited to the neutron-poor thorium fuel cycle.

In some thorium breeding scenarios, the intermediate product Protactinium233

Pa would be removed from the reactor and allowed to decay into highly pure 233

U, an attractive bomb-making material. More modern designs propose to use a lower specific power or a separate thorium breeding blanket. This dilutes the protactinium to such an extent that few protactinium atoms absorb a second neutron or, via a (n, 2n) reaction (in which an incident neutron is not absorbed but instead knocks a neutron out of the nucleus), generate 232

U. Because 232

U has a short half-life and its decay chain contains hard gamma emitters, it makes the isotopic mix of uranium less attractive for bomb-making. This benefit would come with the added expense of a larger fissile inventory or a 2-fluid design with a large quantity of blanket salt.

The necessary fuel salt reprocessing technology has been demonstrated, but only at laboratory scale. A prerequisite to full-scale commercial reactor design is the R&D to engineer an economically competitive fuel salt cleaning system.

Fuel cycle can be either closed or once-through.[4]

Reprocessing refers to the chemical separation of the constituents of spent nuclear fuel (Wikipedia ref to nuclear reprocessing). Reprocessing is a loaded term in the context of nuclear proliferation in that it could be used to extract fissionable material, particularly uranium or plutonium, out of which a nuclear bomb could be made, and hence is subject to regulatory oversight and restrictions. Partly due to proliferation concerns and partly for economic reasons, the US has never reprocessed commercial spent nuclear fuel.[62]

In the context of an MSR, fuel reprocessing, as opposed to the removal of fission products and impurities described above under "fuel purification", is relevant (see Wikipedia Protactinium article) in certain breeder reactors containing thorium, separation of 233Pa: Protactinium-233 is formed upon neutron capture by 232Th. It further either decays to uranium-233 or captures another neutron and converts into the non-fissile uranium-234.[32] 233Pa has a relatively long half-life of 27 days and high cross section for neutron capture (the so-called "neutron poison"). Thus, instead of rapidly decaying to the useful 233U, a significant fraction of 233Pa converts to non-fissile isotopes and consumes neutrons, degrading the reactor efficiency. To avoid this, 233Pa is extracted from the active zone of thorium molten salt reactors during their operation, so that it only decays to 233U. (check against LFTR design)

Because the 233U thus obtained is suitable for bomb-making, it represents a proliferation risk.

In the 1971 Molten Salt Breeder Reactor proposal, uranium reprocessing was scheduled every ten days as part of reactor operation.[63]: 181 Subsequently, a once-through fueling design was proposed that limited uranium reprocessing to every thirty years at the end of useful salt life.[21]: 98 A mixture with 238

U was called for to make sure recovered uranium would not be weapons-grade. This design is referred to as denatured molten salt reactor.[64] With no reprocessing, the uranium would be disposed with other fission products.

molten salt-specific passive safety features[edit]

Negative temperature coefficient of reactivity (Doppler, thermal expansion of fuel; often also ancillary materials such as moderator graphite or diagrid). Void coefficient can be positive, depending on design. Combination with wide operating temperature range can allow total lack of active control elements (except for emergency) Freeze plug / drain tanks Low-pressure operation Fission product binding passive heat removal to air

Molten salts can be highly corrosive and corrosivity increases with temperature. For the primary cooling loop, a material is needed that can withstand corrosion at high temperatures and intense radiation. Experiments show that Hastelloy-N and similar alloys are suited to these tasks at operating temperatures up to about 700 °C. However, operating experience is limited. Still higher operating temperatures are desirable—at 850 °C thermochemical production of hydrogen becomes possible. Materials for this temperature range have not been validated, though carbon composites, molybdenum alloys (e.g. TZM), carbides, and refractory metal based or ODS alloys might be feasible.

A workaround suggested by a private researcher is to use the new beta-titanium Au alloys as this would also allow extreme temperature operation as well as increasing the safety margin.[citation needed]

Dual-fluid molten salt reactors[edit]

A prototypical example of a dual fluid reactor is the lead-cooled, salt-fueled reactor.

Fused salt selection[edit]

Mixtures (salt mixture table: default compressed; note relevant to thermal rather than fast)

mechanical, heat transport

The salt mixtures, typically metal halides, are chosen to make the reactor safer and more practical.

Fluorine[edit]

Fluorine has only one stable isotope (F-19), and does not easily become radioactive under neutron bombardment. Compared to chlorine and other halides, fluorine also absorbs fewer neutrons and slows ("moderates") neutrons better. Low-valence fluorides boil at high temperatures, though many pentafluorides and hexafluorides boil at low temperatures. They must be very hot before they break down into their constituent elements. Such molten salts are "chemically stable" when maintained well below their boiling points. Fluoride salts dissolve poorly in water, and do not form burnable hydrogen.

Chlorine[edit]

Chlorine has two stable isotopes (35

Cl and 37

Cl), as well as a slow-decaying isotope between them which facilitates neutron absorption by 35

Cl.

Chlorides permit fast breeder reactors to be constructed. Much less research has been done on reactor designs using chloride salts. Chlorine, unlike fluorine, ???? must be purified to isolate the heavier stable isotope, chlorine-37, thus reducing production of sulfur tetrachloride that occurs when chlorine-35 absorbs a neutron to become chlorine-36, then degrades by beta decay to sulfur-36.

Lithium[edit]

Lithium must be in the form of purified 7

Li, because 6

Li effectively captures neutrons and produces tritium. Even if pure 7Li is used, salts containing lithium cause significant tritium production, comparable with heavy water reactors.

Mixtures[edit]

Reactor salts are usually close to eutectic mixtures to reduce their melting point. A low melting point simplifies melting the salt at startup and reduces the risk of the salt freezing as it is cooled in the heat exchanger.

Due to the high "redox window" of fused fluoride salts, the redox potential of the fused salt system can be changed. Fluorine-Lithium-Beryllium ("FLiBe") can be used with beryllium additions to lower the redox potential and almost eliminate corrosion. However, since beryllium is extremely toxic, special precautions must be engineered into the design to prevent its release into the environment. Many other salts can cause plumbing corrosion, especially if the reactor is hot enough to make highly reactive hydrogen.

To date, most research has focused on FLiBe, because lithium and beryllium are reasonably effective moderators and form a eutectic salt mixture with a lower melting point than each of the constituent salts. Beryllium also performs neutron doubling, improving the neutron economy. This process occurs when the beryllium nucleus emits two neutrons after absorbing a single neutron. For the fuel carrying salts, generally 1% or 2% (by mole) of UF4 is added. Thorium and plutonium fluorides have also been used.

| Material | Total neutron capture relative to graphite (per unit volume) |

Moderating ratio (Avg. 0.1 to 10 eV) |

|---|---|---|

| Heavy water | 0.2 | 11449 |

| ZrH[66][67][68] | ~0.2 | ~0 if <0.14 eV, ~11449 if >0.14 eV |

| Light water | 75 | 246 |

| Graphite | 1 | 863 |

| Sodium | 47 | 2 |

| UCO | 285 | 2 |

| UO2 | 3583 | 0.1 |

| 2LiF–BeF2 | 8 | 60 |

| LiF–BeF2–ZrF4 (64.5–30.5–5) | 8 | 54 |

| NaF–BeF2 (57–43) | 28 | 15 |

| LiF–NaF–BeF2 (31–31–38) | 20 | 22 |

| LiF–ZrF4 (51–49) | 9 | 29 |

| NaF–ZrF4 (59.5–40.5) | 24 | 10 |

| LiF-NaF–ZrF4 (26–37–37) | 20 | 13 |

| KF–ZrF4 (58–42) | 67 | 3 |

| RbF–ZrF4 (58–42) | 14 | 13 |

| LiF–KF (50–50) | 97 | 2 |

| LiF–RbF (44–56) | 19 | 9 |

| LiF–NaF–KF (46.5–11.5–42) | 90 | 2 |

| LiF–NaF–RbF (42–6–52) | 20 | 8 |

Advantages and disadvantages[edit]

Advantages and disadvantages must be assessed with appropriate caution. Although different designs have attracted ardent supporters, both Admiral Rickover's dictum and Murphy's Law, as well as the unpredictability of regulators' risk assessment and mandated countermeasures, put the burden of proof on developers to empirically demonstrate both the reality of the advantages and the absence of unforeseen drawbacks.

Comparison to light water reactors[edit]

MSRs, especially those with the fuel dissolved in the salt, differ considerably from conventional reactors. Reactor core pressure can be low and the temperature much higher. In this respect an MSR is more similar to a liquid metal cooled reactor than to a conventional light water cooled reactor. MSRs are often planned as breeding reactors with a closed fuel cycle—as opposed to the once-through fuel currently used in U.S. nuclear reactors.

Safety concepts rely on a negative temperature coefficient of reactivity and a large possible temperature rise to limit reactivity excursions. As an additional method for shutdown, a separate, passively cooled container below the reactor can be included. In case of problems and for regular maintenance the fuel is drained from the reactor. This stops the nuclear reaction and acts as a second cooling system. Neutron-producing accelerators have been proposed for some super-safe subcritical experimental designs.[69]

Cost estimates from the 1970s were slightly lower than for conventional light-water reactors.[70]

The temperatures of some proposed designs are high enough to produce process heat for hydrogen production or other chemical reactions. Because of this, they are included in the GEN-IV roadmap for further study.[71]

?????? - non-solid fuel reduces purity requirements, facilitates waste burning in fast variants

Advantages[edit]

MSRs offer many potential advantages over current light water reactors:[9]

- As in all low-pressure reactor designs, passive decay heat removal is achieved in MSRs. In some designs, the fuel and the coolant are the same fluid, so a loss of coolant removes the reactor's fuel, similar to how loss of coolant also removes the moderator in LWRs. Unlike steam, fluoride salts dissolve poorly in water, and do not form burnable hydrogen. Unlike steel and solid uranium oxide, molten salts are not damaged by the core's neutron bombardment, though the reactor vessel still is.

- A low-pressure MSR lacks a BWR's high-pressure radioactive steam and therefore do not experience leaks of radioactive steam and cooling water, and the expensive containment, steel core vessel, piping and safety equipment needed to contain radioactive steam. However, most MSR designs require radioactive fission product-containing fluid in direct contact with pumps and heat exchangers.

- MSRs may make closed nuclear fuel cycles cheaper because they can operate with slow neutrons. If fully implemented, any reactor that closes the nuclear fuel cycle reduces environmental impacts: Chemical separation turns long-lived actinides back into reactor fuel. The discharged wastes are mostly fission products (nuclear ashes) with shorter half-lives. This reduces the needed geologic containment to 300 years rather than the tens of thousands of years needed by a light-water reactor's spent nuclear fuel. It also permits the use of alternate nuclear fuels, such as thorium.

- The fuel's liquid phase might be pyroprocessed to separate fission products (nuclear ashes) from actinide fuels. This may have advantages over conventional reprocessing, though much development is still needed.

- Fuel rod fabrication is not required (replaced with fuel salt synthesis).

- Some designs are compatible with the fast neutron spectrum, which can "burn" problematic transuranic elements like Pu240, Pu241 and up (reactor grade plutonium) from traditional light-water nuclear reactors.

- An MSR can react to load changes in less than 60 seconds (unlike "traditional" solid-fuel nuclear power plants that suffer from xenon poisoning).

- Molten salt reactors can run at high temperatures, yielding high thermal efficiency. This reduces size, expense, and environmental impacts.

- MSRs can offer a high "specific power," that is high power at a low mass as demonstrated by ARE.[7]

- A possibly good neutron economy makes the MSR attractive for the neutron poor thorium fuel cycle

Disadvantages[edit]

- Little development compared to most Gen IV designs

- In circulating-fuel-salt designs, radionuclides dissolved in fuel come in contact with major equipment such as pumps and heat exchangers, likely requiring fully remote and possibly expensive maintenance.

- Required onsite chemical plant to manage core mixture and remove fission products

- Required regulatory changes to deal with radically different design features

- MSR designs rely on nickel-based alloys to hold the molten salt. Alloys based on nickel and iron are prone to embrittlement under high neutron flux.[21]: 83

- Corrosion risk.[72] Molten salts require careful management of their redox state to handle corrosion risks. This is particularly challenging for circulating-fuel-salt designs, in which a complex mix of fissile/fertile isotopes and their transmutation/fission/decay products is being circulated through the reactor. Static fuel salt designs profit from modularising the problem: the fuel salt is contained within fuel pins whose regular replacement, primarily due to neutron irradiation damage, is part of the operating concept; while the coolant salt has a simpler chemical composition and, under appropriate redox state management, does not pose a corrosion risk either to the fuel pins or to the reactor vessel. (Regarding redox state management, see the descriptions for the Stable salt reactor's fuel and coolant salts). The MSRs developed at ORNL in the 60's were only safe to operate for a few years, and operated at only about 650C. Potential corrosion risks include dissolution of chromium by liquid fluoride thorium salts at 700+C, hence endangering stainless steel components. Neutron radiation can also transmute other common alloying agents such as Co and Ni, shortening lifespan. If using lithium salts (e.g. FLiBe), it is preferable, if expensive, to use 7Li to reduce tritium generation (tritium can permeate stainless steels, cause embrittlement, and escape into the environment). ORNL developed Hastelloy N to help address these issues, and there is an effort to certify other structural steels to for use in reactors (316H, 800H, inco 617).

- As a breeder reactor, a modified MSR might be able to produce weapons-grade nuclear material[73]

- The MSRE and aircraft nuclear reactors used enrichment levels so high that they approach the levels of nuclear weapons. These levels would be illegal in most modern regulatory regimes for power plants. Some modern designs avoid this issue.[74]

- Neutron damage to solid moderator materials can limit the core lifetime of an MSR that uses moderated thermal neutrons. For example, the MSRE was designed so that its graphite moderator sticks had very loose tolerances, so neutron damage could change their size without damage. "Two fluid" MSR designs are unable to use graphite piping because graphite changes size when it is bombarded with neutrons, and graphite pipes would crack and leak.[9] MSR using fast neutrons cannot use graphite anyway to avoid moderation.

- Thermal MSRs have lower breeding ratios than fast-neutron breeders, though their doubling time may be shorter.

Challenges for commercialisation[edit]

Development[edit]

Developing an MSR design to the degree required for a regulator to grant a commercial reactor licence will require significant development work: first fixing values for the design parameters noted above, then validating the performance of components (fuel and/or coolant salt, materials, moving parts such as pumps) and ultimately of the whole reactor system for the full range of normal conditions (startup, steady state operation, refuelling, planned shutdown, emergency shutdown) and outside-normal operating conditions. Relevant parameters to describe operating conditions include temperature; neutronics/criticality including spatial distribution and development over time; and chemical composition, in particular of fuel salt. Of particular interest in evaluating performance will be the durability of materials and moving parts; and the behaviour of the salts over different temperatures, not least their viscosity and ability to retain dissolved/suspended elements (rather than have them bubble or deposit out). While "traditional" coolants such as water and helium have very well-understood and -documented properties over a wide range of conditions, this data is not yet available to the same extent for all candidate salts/salt mixtures. Also, compared to using a single liquid or gas whose state can be characterised almost entirely by temperature, pressure and flow rate/direction, a molten fuel salt addionally has a varying composition caused by fission, transmutation and decay; for circulating fuel salt designs, delayed neutrons mean that reactivity can be affected by flow rates, and reprocessing/purification also impacts fuel composition. This multiplicity of state dimensions makes it more challenging to prove safe behaviour across all relevant operating conditions.

To date no formal licence application has been submitted to a developed-country nuclear regulator for a commercial MSR. While not all interactions with regulators are matters of public record, Canada's "Vendor Design Review" (VDR) process shows that two designs have been submitted for early-stage review: Terrestrial Energy's circulating fuel salt IMSR completed Vendor Design Review (VDR) Phase 1 in 2017 and is currently in VDR Phase 2, while Moltex Energy's static fuel salt SSR-W is currently in VDR Phase 1.

Establishment of molten salt fuel cycle[edit]

Molten salt fuel must be manufactured. In addition to simply heating and reacting/mixing the component elements, certain components of both coolant and fuel salt may require isotopic purification (e.g. lithium/chlorine). For static fuel salt designs, fuel pins/assemblies must be manufactured and filled with fuel salt.

Nuclear waste from an MSR is different to that from a conventional LWR: while LWR spent fuel typically binds its fission products and actinide transmutation products within the fuel's ceramic (metal oxide) matrix, an MSR can produce multiple waste streams, some in liquid and gaseous form. Containers and storage for these novel waste streams must be developed and qualified; additional processing steps may be necessary to prepare the wastes for safe disposal; the criteria for geological suitability of a disposal site may be different as a result.

Both fuel fabrication and reprocessing facilities involve handling radioactive material and require licensing by the respective nuclear regulator, with all the associated multi-year cost and effort to validate and demonstrate the safety of the proposed designs.

Licensing[edit]

Historically, licensing has been strongly focused on water-cooled reactors (with some notable exceptions such as the UK's gas-cooled reactors). Subsequent tightening of safety requirements in the wake of Chernobyl and Fukushima further rigidified this focus. This means that developers using other coolants and their regulators need to both "start from scratch" in finding suitable detailed design criteria by which the regulator can judge the safety of the design, and challenge/abandon some established criteria as no longer relevant. Given the large body of existing regulation and the low tolerance for residual risk, these are highly time-consuming and difficult discussions. Some regulators, notably Canada's CNSC, have made a point of opening up their licensing process to new designs; in recent years the US NRC has begun a programme of activity to engage with licensing advanced reactor designs. On the positive side, regulators are also considering international cooperation and knowledge exchange, e.g. between the US NRC and Canada's CNSC, and between Canada and the UK, which is intended to reduce the barriers to entry into subsequent markets for a design with a first licence.

See also[edit]

References[edit]

- ^ Moltex Energy. "Static fuel salt reactor (cutaway diagram)". Retrieved 2 January 2021.

- ^ ResearchGate. Andreades/publication/307513611/figure/fig5/AS:461757325025285@1487102933610/The-Mk1-PB-FHR-reactor-vessel.png "Molten salt coolant only reactor diagram". Retrieved 2 January 2021.

{{cite web}}: Check|url=value (help) - ^ Mignacca, Benito; Locatelli, Giorgio (November 2020). "Economics and finance of Molten Salt Reactors". Progress in Nuclear Energy. 129: 103503. doi:10.1016/j.pnucene.2020.103503.

- ^ a b Wang, Brian (2018-08-26). "Global race for transformative molten salt nuclear includes Bill Gates and China". NextBigFuture.com. Retrieved 2018-09-02.

- ^ Gat, U.; Engel, J. R.; Dodds, H. L. (1 January 1991). The Molten Salt Reactor option for beneficial use of fissile material from dismantled weapons. Annual meeting of the American Association for the Advancement of Science: earth science. OSTI 5717860.

- ^ "Molten Salt Reactors". World Nuclear Association.

- ^ a b Rosenthal, Murry. An Account of Oak Ridge National Laboratory's Thirteen Nuclear Reactors, ORNL/TM-2009/181.

- ^ Scott, D; Alwang, G W; Demski, E F; Fader, W J; Sandin, E V; Malenfant, R E (14 August 1958). "A Zero Power Reflector-Moderated Reactor Experiment at Elevated Temperature": ORNL–2536, 4673343. doi:10.2172/4673343. OSTI 4673343.

{{cite journal}}: Cite journal requires|journal=(help) - ^ a b c Section 5.3, WASH 1097. Energy From Thorium's Document Repository "The Use of Thorium in Nuclear Power Reactors". ORNL.gov

- ^ a b "The UK's Forgotten Molten Salt Reactor Programme". The Alvin Weinberg Foundation. Archived from the original on 2016-03-05.

- ^ Smith, J; Simmons, W E (eds.). "An Assessment of a 2500 MEe Molten Chloride Salt Fast Reactor" (PDF). United Kingdom Atomic Energy Authority Reactor Group. Retrieved 13 June 2015.

- ^ May, W C; Simmons, W E (eds.). "Conceptual Design and Assessment of a Helium-cooled 2500 MEe Molten Salt Reactor With Integrated Gas Turbine Plant" (PDF). United Kingdom Atomic Energy Authority Reactor Group. Retrieved 13 June 2015.

- ^ a b c MacPherson, H. G. (1985). "The Molten Salt Reactor Adventure" (PDF). Nuclear Science and Engineering. 90 (4): 374–380. doi:10.13182/NSE90-374.

- ^ Weinberg, Alvin (1997). The First Nuclear Era: The Life and Times of a Technological Fixer. Springer. ISBN 978-1-56396-358-2.

- ^ "Chapter 6: Responding To Social Needs". ORNL: The First 50 Years. Retrieved 12 November 2011.

- ^ Johnston, Louis; Williamson, Samuel H. (2023). "What Was the U.S. GDP Then?". MeasuringWorth. Retrieved November 30, 2023. United States Gross Domestic Product deflator figures follow the MeasuringWorth series.

- ^ Cohen, Linda R.; Noll, Roger G. (1991). The Technology pork barrel. Brookings Institution. p. 234. ISBN 978-0-8157-1508-5. Retrieved 28 February 2012.

- ^ Novikov, Vladimir M. (15 September 1995). "The results of the investigations of Russian Research Center—'Kurchatov Institute' on molten salt applications to problems of nuclear energy systems". AIP Conference Proceedings. 346 (1): 138–147. Bibcode:1995AIPC..346..138N. doi:10.1063/1.49148.

- ^ A reduction in activity occurred after 1986 due to the Chernobyl accident, along with a general stagnation of nuclear power and the nuclear industry.

- ^ Agency, Nuclear Energy; OECD (1999). Advanced Reactors with Innovative Fuels. p. 381. ISBN 978-9264171176.

- ^ a b c Engel, J.R.; Bauman, H.F.; Dearing, J.F.; Grimes, W.R.; McCoy, H.E.; Rhoades, W.A. (1 July 1980). "Conceptual design characteristics of a denatured molten-salt reactor with once-through fueling": ORNL/TM–7207, 5352526. doi:10.2172/5352526. OSTI 5352526.

{{cite journal}}: Cite journal requires|journal=(help) - ^ Greene, Sherrel (May 2011). Fluoride Salt-cooled High Temperature Reactors – Technology Status and Development Strategy. San Francisco, CA.

{{cite book}}: Unknown parameter|book-title=ignored (help)CS1 maint: location missing publisher (link) - ^ Fluoride Salt-Cooled High-Temperature Reactor Workshop Announcement and Call for Participation, September 2010, at Oak Ridge National Laboratory, Oak Ridge Tennessee

- ^ a b Evans-Pritchard, Ambrose (6 January 2013) China blazes trail for 'clean' nuclear power from thorium The Daily Telegraph, UK. Accessed 18 March 2013

- ^ Clark, Duncan (16 February 2011). "China enters race to develop nuclear energy from thorium". The Guardian.

- ^ Halper, Mark. "China eyes thorium MSRs for industrial heat, hydrogen; revises timeline". Weinberg Next Nuclear. The Alvin Weinberg Foundation. Retrieved 9 June 2016.

- ^ a b c Chen, Stephen (5 December 2017). "China Hopes Cold War Nuclear Energy Tech Will Power Warships, Drones". South China Morning Post. Retrieved 4 May 2018.

- ^ Tennenbaum, Jonathan (2020-02-04). "Molten salt and traveling wave nuclear reactors". Asia Times. Retrieved 2020-09-30.

- ^ Integral Molten Salt Reactor. terrestrialenergy.com

- ^ "Pre-Licensing Vendor Design Review". Canadian Nuclear Safety Commission. Retrieved 10 November 2017.

- ^ https://www.dualports.eu/wp-content/uploads/2019/06/Seaborg-making-nuclear-sustainable.pdf.

{{cite web}}: Missing or empty|title=(help) - ^ "http://seaborg.co/".

{{cite web}}: External link in|title= - ^ "New nuke could power world until 2083". The Register. 14 March 2013.

- ^ Transatomic (September 25, 2018). "Transatomic Power". Twitter. Retrieved October 13, 2019.

- ^ a b Kirk Sorensen has Started a Thorium Power Company Archived 26 October 2011 at the Wayback Machine at NextBigFuture blog, 23 May 2011

- ^ "Flibe Energy". flibe-energy.com.

- ^ "Live chat: nuclear thorium technologist Kirk Sorensen". The Guardian. 7 September 2011.

- ^ "New Huntsville company to build thorium-based nuclear reactors" Archived 6 April 2012 at the Wayback Machine. huntsvillenewswire.com.

- ^ a b Barton, Charles (March 2008) Interview with Ralph Moir at Energy From Thorium blog

- ^ Hargraves, Robert; Moir, Ralph (2010). "Liquid Fluoride Thorium Reactors". American Scientist. 98 (4): 304–313. doi:10.1511/2010.85.304. JSTOR 27859537. ProQuest 847558669.

- ^ Van Gosen, B. S.; Armbrustmacher, T. J. (2009), Thorium deposits of the United States – Energy resources for the future?, vol. Circular 1336, U.S. Geological Survey

- ^ Fuji Molten salt reactor Archived 5 February 2010 at the Wayback Machine. nextbigfuture.com. 19 December 2007

- ^ "Advances in Small Modular Reactor Technology Developments" (PDF). International Atomic Energy Agency (IAEA). Retrieved 22 December 2019.

- ^ Copenhagen Atomics - Thomas Jam Pedersen @ TEAC10. YouTube. 17 November 2019. Retrieved 22 December 2019.

- ^ Griffiths, Trevor; Tomlinson, Jasper; O’Sullivan, Rory. "MSR Review – Feasibility of Developing a Pilot Scale Molten Salt Reactor in the UK" (PDF). Energy Process Developments. Retrieved 14 January 2016.

- ^ Ian Scott (2017-06-20), "Molten Salt Reactors", The Nuclear Institute UK, retrieved 2018-03-18 – via YouTube[dead link]

- ^ "Moltex partners in New Brunswick SMR project", World Nuclear News, July 16, 2018

- ^ "Karios, Moltex, See Progress in Funding; First Canadian SMR, an HTGR, Submits License Application to CNSC", Neutron Bytes, April 6, 2019

- ^ "Current pre-licensing vendor design reviews", Canadian Nuclear Safety Commission, retrieved 8 June 2020

- ^ "European Commission : CORDIS : Projects & Results Service : Periodic Report Summary – EVOL (Evaluation and viability of liquid fuel fast reactor system)". Archived from the original on 2016-04-13.

- ^ "EVOL (Project n°249696) Final Report" (PDF).

- ^ Serp, Jérôme; Allibert, Michel; Beneš, Ondřej; Delpech, Sylvie; Feynberg, Olga; Ghetta, Véronique; Heuer, Daniel; Holcomb, David; Ignatiev, Victor; Kloosterman, Jan Leen; Luzzi, Lelio; Merle-Lucotte, Elsa; Uhlíř, Jan; Yoshioka, Ritsuo; Zhimin, Dai (1 November 2014). "The molten salt reactor (MSR) in generation IV: Overview and perspectives". Progress in Nuclear Energy. 77: 308–319. doi:10.1016/j.pnucene.2014.02.014.

- ^ "SAMOFAR home". SAMOFAR. Retrieved 2018-08-31.

- ^ Vijayan, P. K.; Basak, A.; Dulera, I. V.; Vaze, K. K.; Basu, S.; Sinha, R. K. (1 September 2015). "Conceptual design of Indian molten salt breeder reactor". Pramana. 85 (3): 539–554. Bibcode:2015Prama..85..539V. doi:10.1007/s12043-015-1070-0. S2CID 117404500.

- ^ "Indian Molten Salt Breeder Reactor (IMSBR) Initiated". Thorium Energy World. Retrieved 2018-08-31.

- ^ "Energy Department Announces New Investments in Advanced Nuclear Power Reactors..." US Department of Energy. Retrieved 16 January 2016.

- ^ "Research clarifies origin of superior properties of new materials for next-generation molten salt reactors - ANSTO". ansto.gov.au.

- ^ "Molten salt reactor research develops class of alloys". world-nuclear-news.org. World Nuclear News.

- ^ C. Forsberg, Charles (June 2004). "Safety and Licensing Aspects of the Molten Salt Reactor" (PDF). 2004 American Nuclear Society Annual Meeting. Pittsburgh, PA: American Nuclear Society. Archived from the original (PDF) on 13 January 2010. Retrieved 12 September 2009.

- ^ a b c Shaffer, J.H. (1 January 1971). "Preparation and Handling of Salt Mixtures for the Molten Salt Reactor Experiment": ORNL––4616, 4074869. doi:10.2172/4074869. OSTI 4074869.

{{cite journal}}: Cite journal requires|journal=(help) - ^ Ignatiev, Victor (1 April 2010). Critical issues of nuclear energy systems employing molten salt fluorides (PDF). Lisbon, Portugal: ACSEPT. Archived from the original (PDF) on 13 April 2016. Retrieved 18 December 2011.

{{cite book}}: Unknown parameter|book-title=ignored (help) - ^ Andrews, Anthony (27 March 2008), "Nuclear Fuel Processing: U.S. Policy Development" (PDF), CRS Report for Congress, RS22542

- ^ Rosenthal, M.; Briggs, R.; Haubenreich, P. (1 January 1971). "Molten-Salt Reactor Program: Semiannual Progress Report for Period Ending August 31, 1971": ORNL––4676, 4743040. doi:10.2172/4743040. OSTI 4743040.

{{cite journal}}: Cite journal requires|journal=(help) - ^ LeBlanc, D (2010). "Denatured Molten Salt Reactors (DMSR): An Idea Whose Time Has Finally Come?". 31st Annual Conference of the Canadian Nuclear Society & 34th CNS: Montreal, Quebec, Canada, 24-27 May, 2010. Canadian Nuclear Society. ISBN 978-1-61782-363-3. S2CID 53394595.

- ^ Ingersoll, D. T. (December 2005). "ORNL/TM-2005/218, Status of Physics and Safety Analyses for the Liquid-Salt-Cooled Very High-Temperature Reactor (LS-VHTR)". ORNL. Retrieved 13 May 2010.

- ^ Baron, Matthias; Böck, Helmuth; Villa, Mario. "TRIGA Reactor Characteristics". IAEA Education and Training. IAEA. Retrieved 2 June 2016.

- ^ Gylfe, J.D. "US Patent 3,145,150, Aug. 18, 1954, Fuel Moderator Element for a Nuclear Reactor, and Method of Making". U.S. Patent Office. U.S. Government. Retrieved 2 June 2016.

{{cite web}}: External link in|ref= - ^ Massie, Mark; Dewan, Leslie C. "US 20130083878 A1, April 4, 2013, Nuclear Reactors and Related Methods and Apparatus". U.S. Patent Office. U.S. Government. Retrieved 2 June 2016.

- ^ Furukawa, Kazuo; Kato, Yoshio; Chigrinov, Sergey E. (1995). "Plutonium (TRU) transmutation and 233U production by single-fluid type accelerator molten-salt breeder (AMSB)". AIP Conference Proceedings. 346 (1): 745–751. Bibcode:1995AIPC..346..745F. doi:10.1063/1.49112.

- ^ Moir, M. W. (2002). "Cost of Electricity from Molten Salt Reactors (MSR)" (PDF). 138. Nuclear Technology: 93–95.

{{cite journal}}: Cite journal requires|journal=(help) - ^ "A Technology Roadmap for Generation IV Nuclear Energy Systems" (PDF). 1 March 2003: GIF–001–00, 859105. doi:10.2172/859105. OSTI 859105. S2CID 46766688.

{{cite journal}}: Cite journal requires|journal=(help) - ^ Finnish research network for generation four nuclear energy systems. vtt.fi

- ^ "Is the "Superfuel" Thorium Riskier Than We Thought?". Popular Mechanics. 5 December 2012.

- ^ "Transatomic Power White Paper, v1.0.1, section 1.2" (PDF). Transatomic Power Inc. Archived from the original (PDF) on 5 July 2015. Retrieved 2 June 2016.

Further reading[edit]

- Energy from Thorium's Document Repository Contains scanned versions of many of the U.S. government engineering reports, over ten thousand pages of construction and operation experience. This repository is the main reference for the aircraft reactor experiment and molten-salt fueled reactor's technical discussion.

- Weinberg, Alvin M. (1994). The First Nuclear Era: The Life and Times of a Technological Fixer. Springer Science & Business Media. ISBN 978-1-56396-358-2.

- Bruce Hoglund's Eclectic Interests Home Page Nuclear Power, Thorium, Molten Salt reactors, etc.

- Generation IV International Forum MSR website

- INL MSR workshop summary

- "Molten Salt Chemistry Plays a Prominent Role in Accelerator-Driven Transmutation Systems". Archived from the original on 21 February 2013.

- Material Considerations for Molten Salt Accelerator-based Plutonium Conversion Systems J.H. Devan et al.

- Nuclear goes retro – with a much greener outlook M. Mitchell Waldrop

- Lane, James. A (1958). Fluid Fuel Reactors. Addison-Wesley & US AEC. p. 972.

External links[edit]

- Pacific Northwest National Laboratory – Molten Salt Reactor Fundamentals YouTube

- International Thorium Energy Organisation – www.IThEO.org

- The Molten-Salt Reactor Experiment on YouTube

- Idaho National Laboratory Molten Salt Reactor Fact Sheet

- Energy from Thorium Blog / Website

- Google TechTalks – “Liquid Fluoride Thorium Reactor: What Fusion Wanted To Be” by Dr. Joe Bonometti NASA / Naval Postgraduate School YouTube

- Pebble Bed Advanced High Temperature Reactor

- Thorium Remix LFTR in 5 Minutes and other LFTR Documentaries.

- Kun Chen from Chinese Academy of Sciences on China Thorium Molten Salt Reactor TMSR Program

- Review of Molten Salt Reactor Technology

- Molten Salt Reactors – Ralph Moir

- "MSFR – Bibliography". Archived from the original on 16 November 2015.

- Heuer, D.; Merle-Lucotte, E.; Allibert, M.; Brovchenko, M.; Ghetta, V.; Rubiolo, P. (1 February 2014). "Towards the thorium fuel cycle with molten salt fast reactors". Annals of Nuclear Energy. 64: 421–429. doi:10.1016/j.anucene.2013.08.002.